|

Jalen

Регистрация: 10.11.23

Сообщений: 13

Пол: Мужской

|

оставлено: 23.01.2403:05

https://www.excavator-hydraulic-pump.com/wp-content/uploads/2023/05/Travel-final-drive-for-DOOSAN-DX225-LCA-170401-00039B.webp-1.jpg

The CASE CX210B final drive is a crucial component of the excavator that plays a significant role in its overall performance. In this tutorial, we will explore the functionality and cost analysis of the CASE CX210B final drive.

[b]Exploring Excavator Hydraulics[/b]

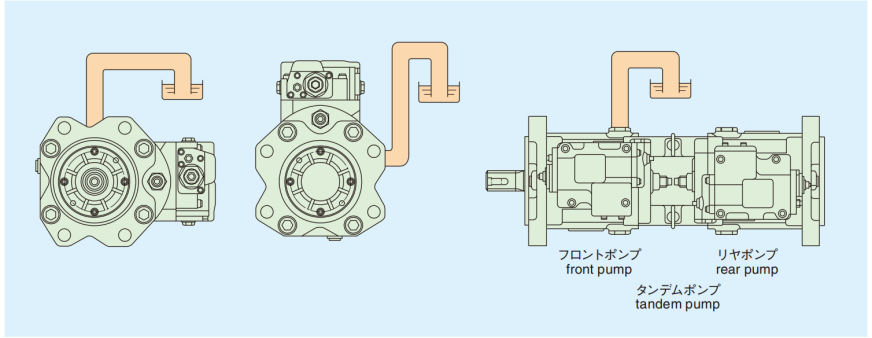

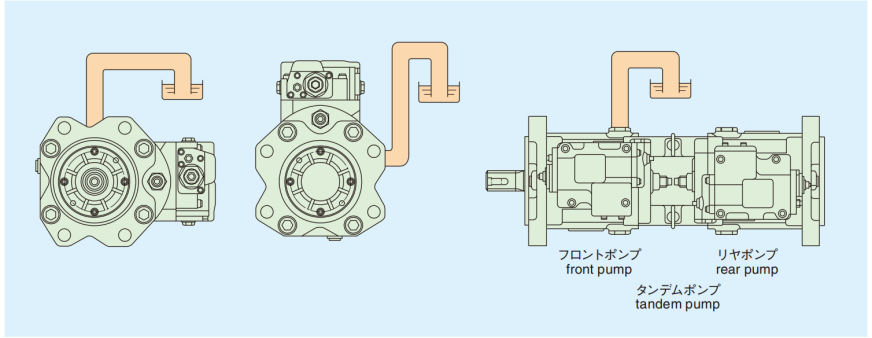

excavator hydraulics are responsible for powering various functions of the machine, including boom movement, bucket operation, and track control. The hydraulic system utilizes fluid pressure to generate force and enable precise movements. It is an essential aspect of any excavator's operation.

[b]An Overview of the CASE CX210B Final Drive[/b]

The CASE CX210B final drive is specifically designed for use in the CASE CX210B excavator model. It serves as a vital component in transferring power from the engine to propel and maneuver the machine efficiently. This final drive ensures smooth rotation of tracks while providing optimal torque output.

The durability and reliability of the CASE CX210B final drive make it suitable for heavy-duty applications in construction, mining, and other demanding industries. Its robust design allows it to withstand harsh operating conditions while delivering consistent performance over extended periods.

[b]CASE CX210B Final Drive Cost Analysis[/b]

When considering purchasing or replacing a CASE CX210B final drive, it is important to conduct a thorough cost analysis. Factors such as initial investment, maintenance requirements, lifespan expectancy, and potential downtime should be taken into account.

In terms of initial investment costs, acquiring a genuine OEM (Original Equipment Manufacturer) replacement may seem more expensive compared to aftermarket options initially; however, OEM parts often provide superior quality assurance and longer lifespan expectancy due to their compatibility with specific equipment models like the CASE CX210B excavator.

Furthermore, the maintenance requirements of the CASE CX210B final drive should be considered. Regular inspections, lubrication, and timely repairs are essential to ensure optimal performance and extend its lifespan. By adhering to recommended maintenance practices, potential downtime can be minimized, resulting in increased productivity and cost savings in the long run.

[b]Conclusion[/b]

The CASE CX210B final drive is a critical component that significantly impacts the overall performance of an excavator. Its robust design and reliable functionality make it suitable for various heavy-duty applications. When considering purchasing or replacing a final drive, conducting a comprehensive cost analysis is crucial to determine the most efficient solution for your specific needs.

|

|

|

estool

Регистрация: 23.01.24

Сообщений: 17

Пол: Мужской

|

оставлено: 23.01.2414:41

|